What is a white ABS plastic sheet and its applications?

As a leading supplier in the industry, we understand the importance of this versatile material and its significant role in various manufacturing and design processes. This article will delve into the properties, characteristics, and numerous applications of white ABS plastic sheet.

What is a white ABS plastic sheet?

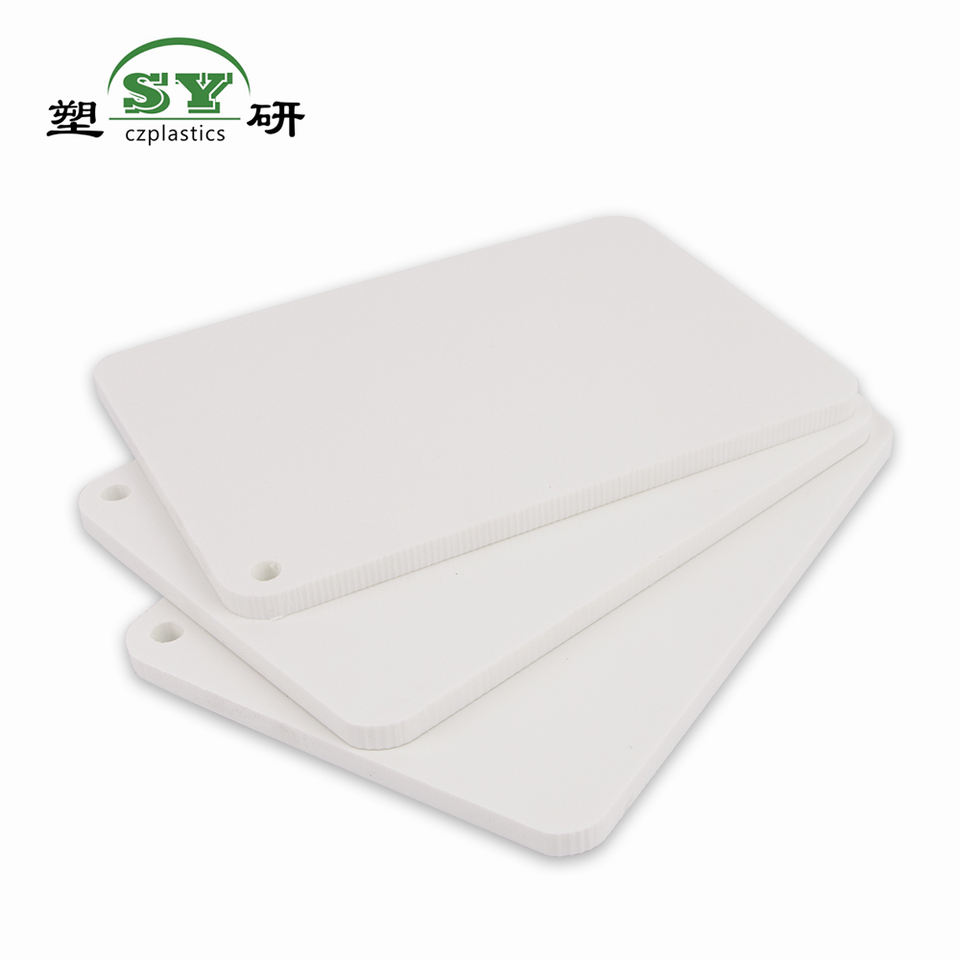

White ABS (Acrylonitrile Butadiene Styrene) plastic sheet is a durable and versatile thermoplastic material widely known for its excellent impact resistance, rigidity, and aesthetic appeal. It comprises three monomers: acrylonitrile, butadiene, and styrene, contributing to its unique properties. White ABS plastic sheet is available in various thicknesses and sizes, making it suitable for various applications.

Properties of white ABS plastic sheet:

1. Impact Resistance:

White ABS plastic sheet exhibits remarkable toughness and can withstand significant impact, making it ideal for durability and strength applications.

2. Rigidity:

Its high rigidity provides structural integrity and dimensional stability to manufactured products.

Aesthetic Appeal: White ABS plastic sheet offers a clean and attractive appearance, making it suitable for applications where visual appeal is essential.

3. Chemical Resistance:

It resists a wide range of chemicals, oils, and solvents, enhancing its suitability for diverse industrial applications.

Machinability: White ABS plastic sheet can be easily machined, drilled, sawed, and bent, allowing for intricate designs and customization.

4. Applications of white ABS plastic sheet:

Automotive Industry: Used for interior and exterior components, such as dashboard panels, trim parts, grilles, and body panels, thanks to its impact resistance and aesthetic appeal.

5. Electronics and Appliances:

White ABS plastic sheet finds applications in producing computer and electronic housings, appliance components, and control panels.

6. Signage and Displays:

It is popularly employed for creating signage, point-of-purchase displays, retail fixtures, and exhibition stands due to its versatility and ease of fabrication.

7. Healthcare and Medical Devices:

White ABS plastic sheet is utilized for manufacturing medical equipment, enclosures, instrument panels, and housings due to its chemical resistance and ease of sterilization.

8. Architecture and Construction:

It is used in interior design elements, wall cladding, decorative panels, and furniture components due to its aesthetic appeal and ease of fabrication.

9. Educational Materials:

White ABS plastic sheet is commonly used for educational models, prototypes, and craft projects due to its affordability and ease of handling.

White ABS plastic sheet is a versatile material with various applications in various industries. Its exceptional impact resistance, rigidity, aesthetic appeal, and chemical resistance make it an ideal choice for the automotive, electronics, signage, healthcare, construction, and educational sectors. We are here to assist you when sourcing high-quality white ABS plastic sheet for your specific needs.