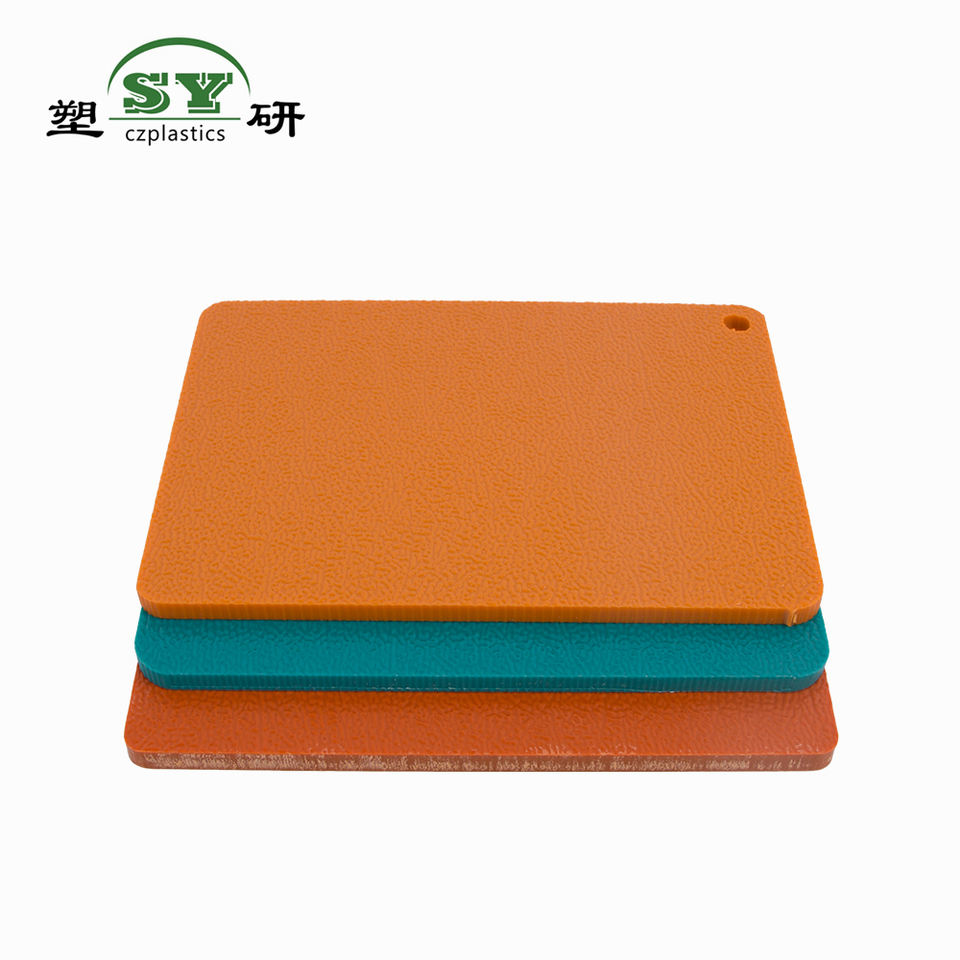

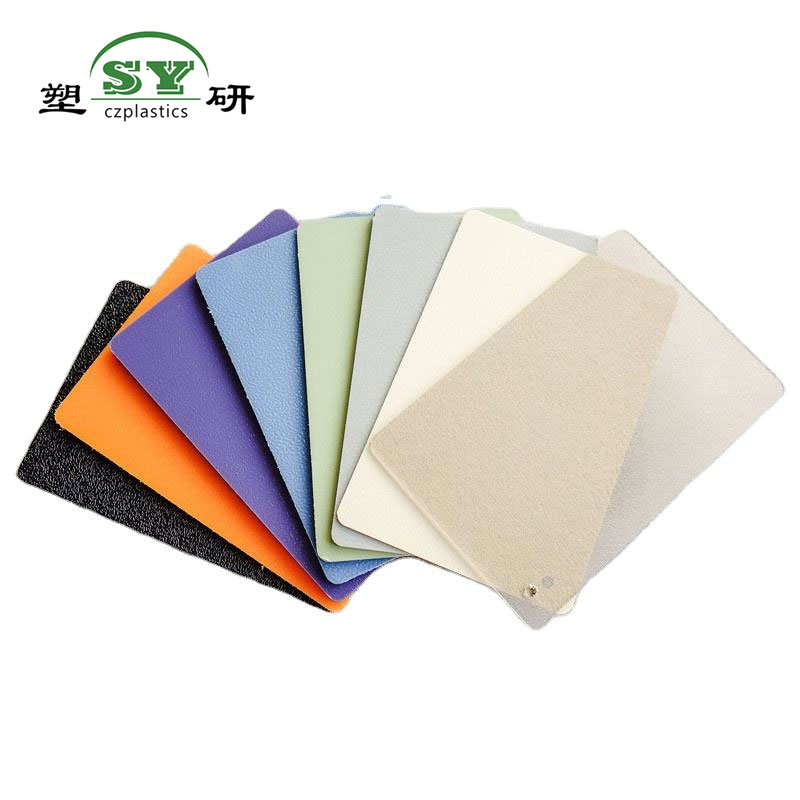

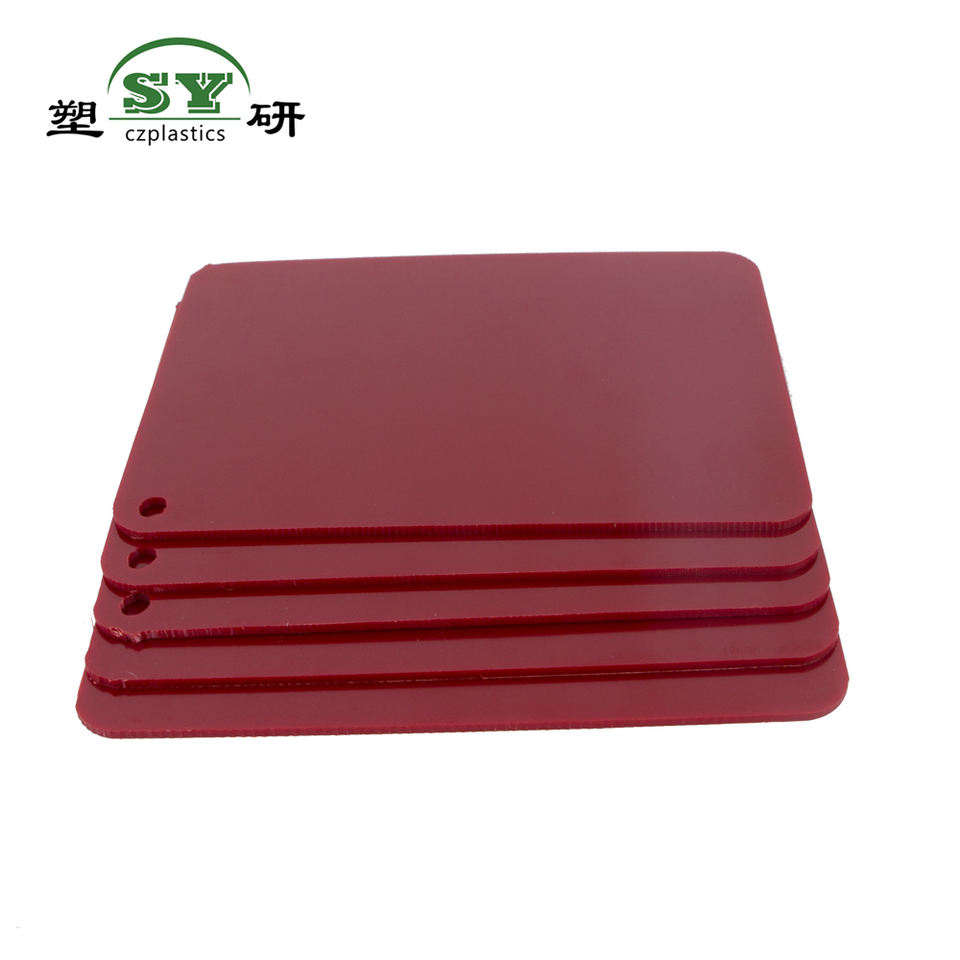

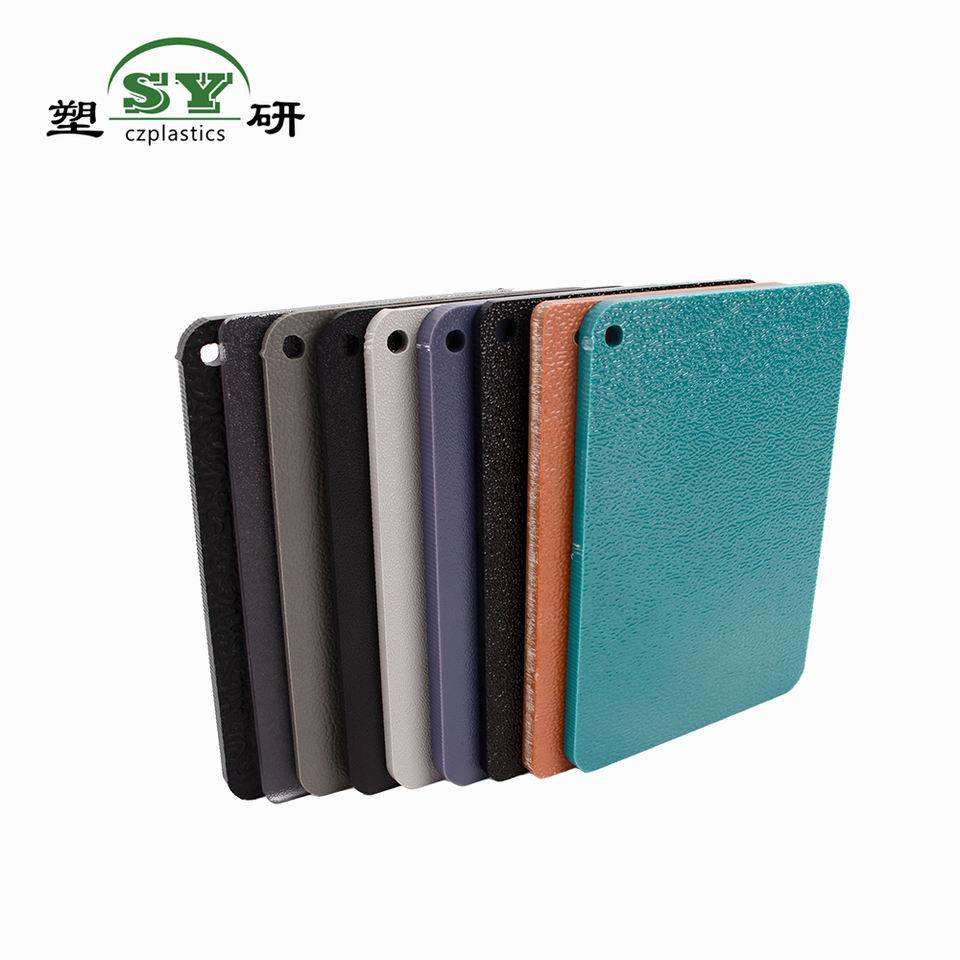

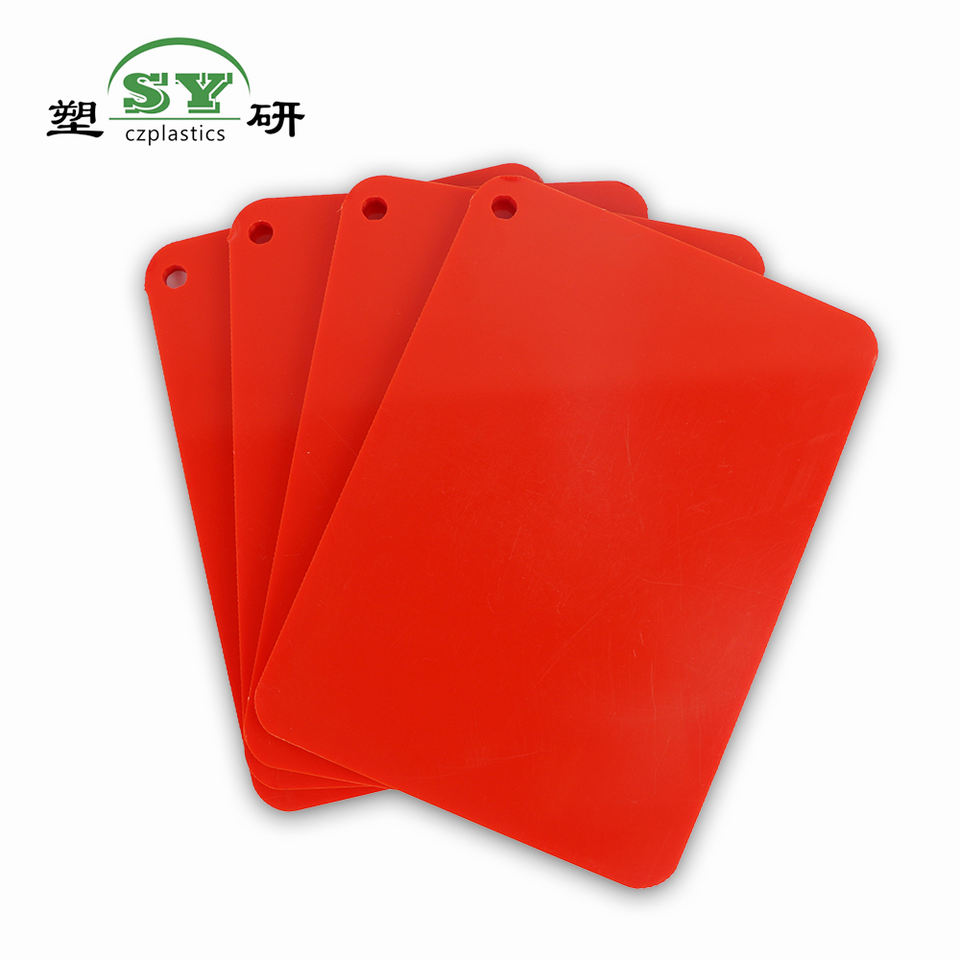

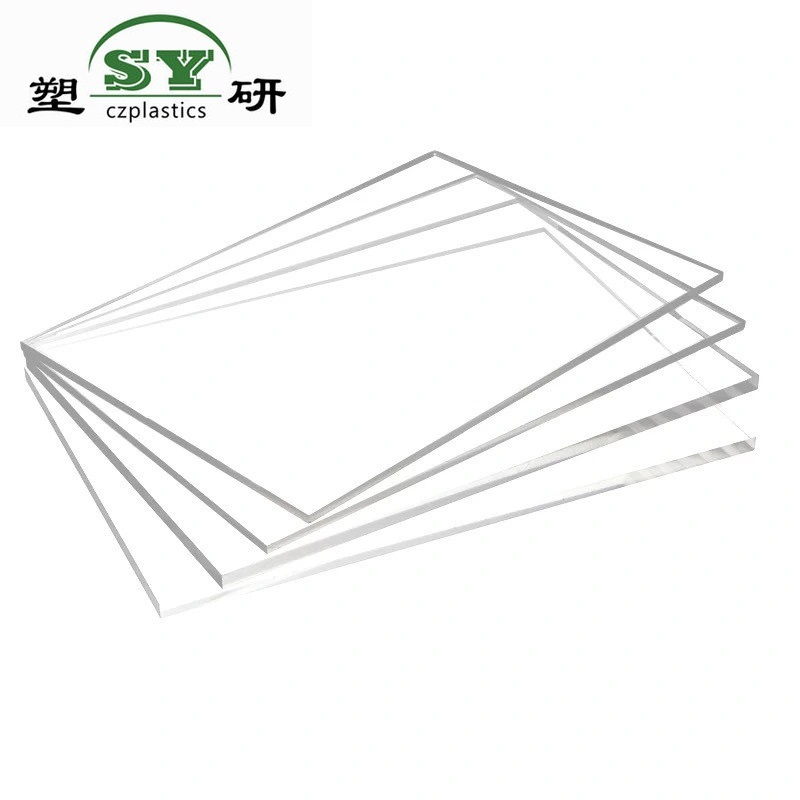

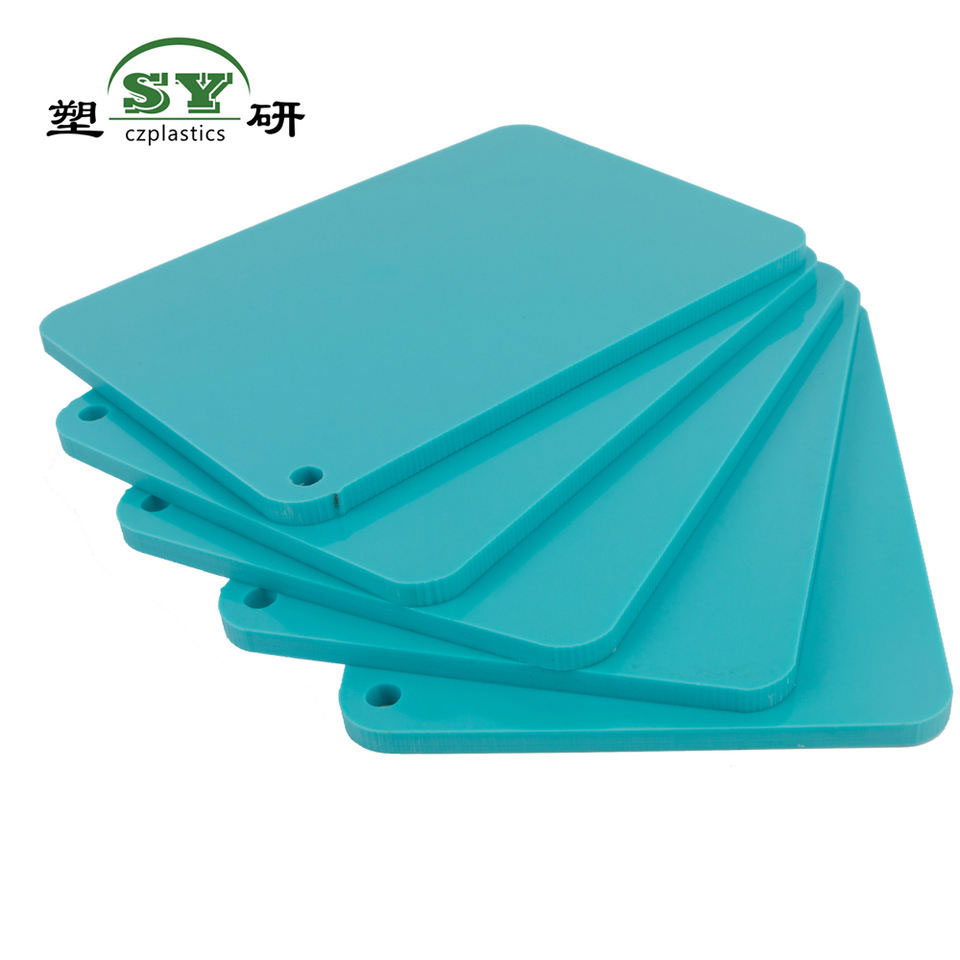

ABS Sheet with Pattern SY04

This Thick thermoforming abs plastic sheets with Pattern is widely used as Interior trim of car or train, Billboards, a variety of display, food industry parts, architectural models, prototype production, into phase electronic industrial parts, refrigerators industry, electronics and chemical industries and other fields.