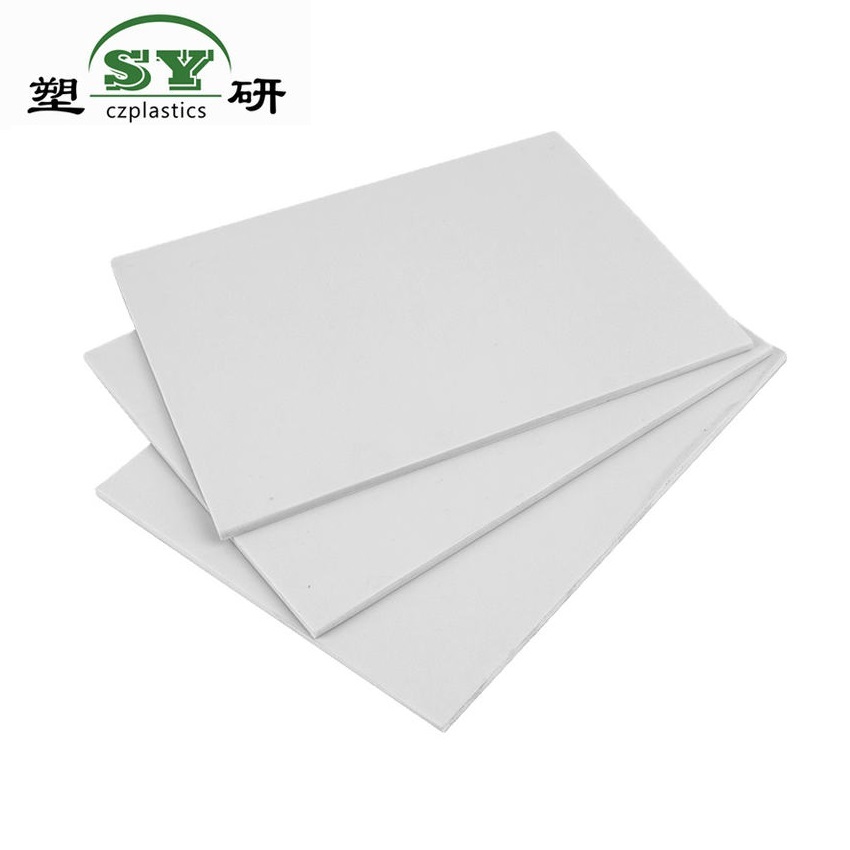

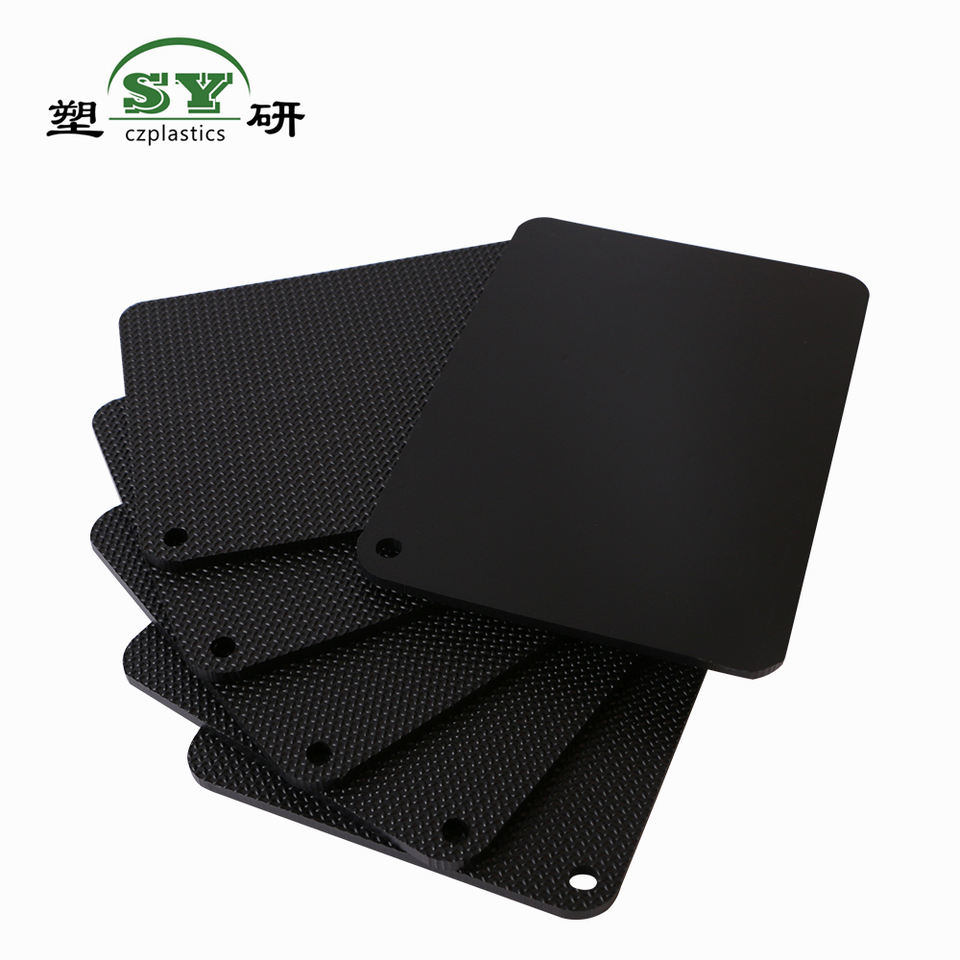

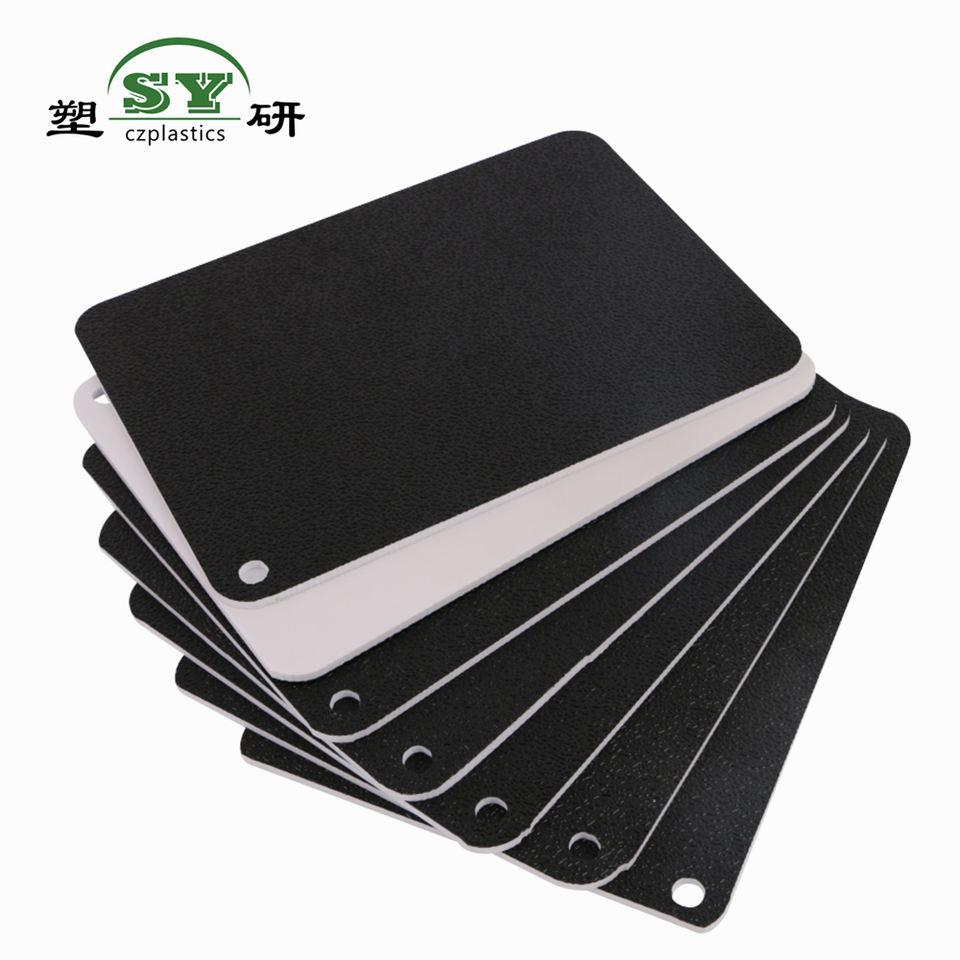

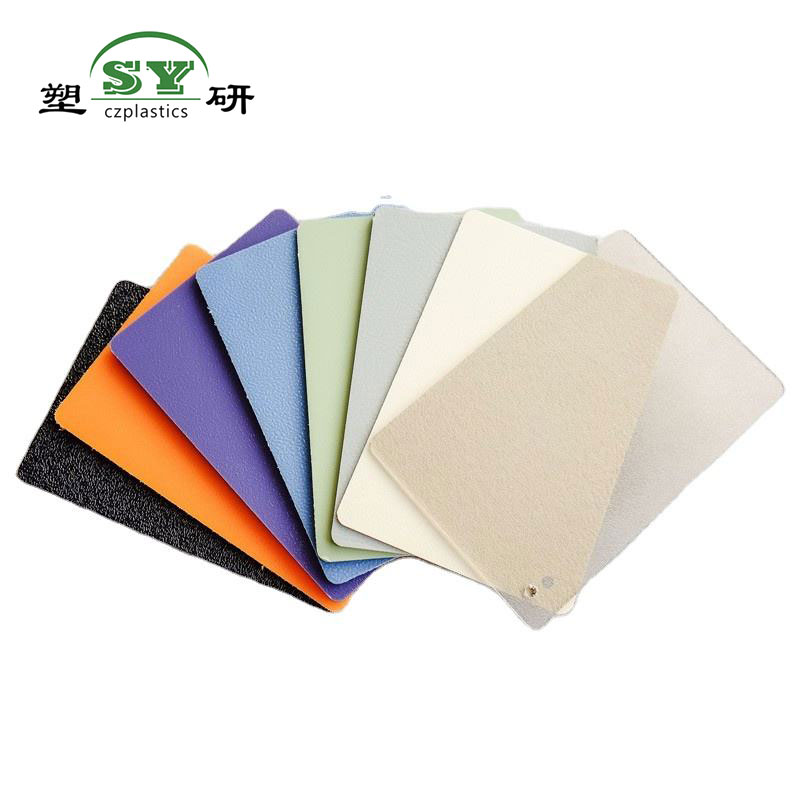

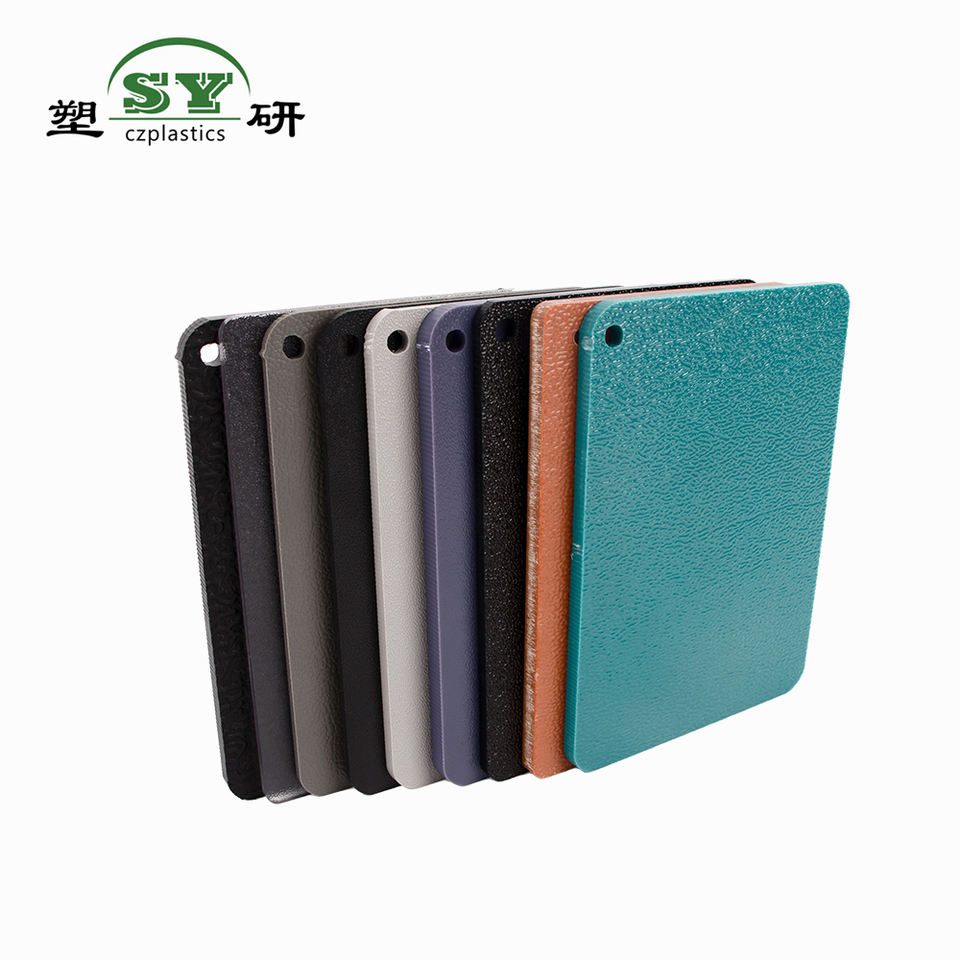

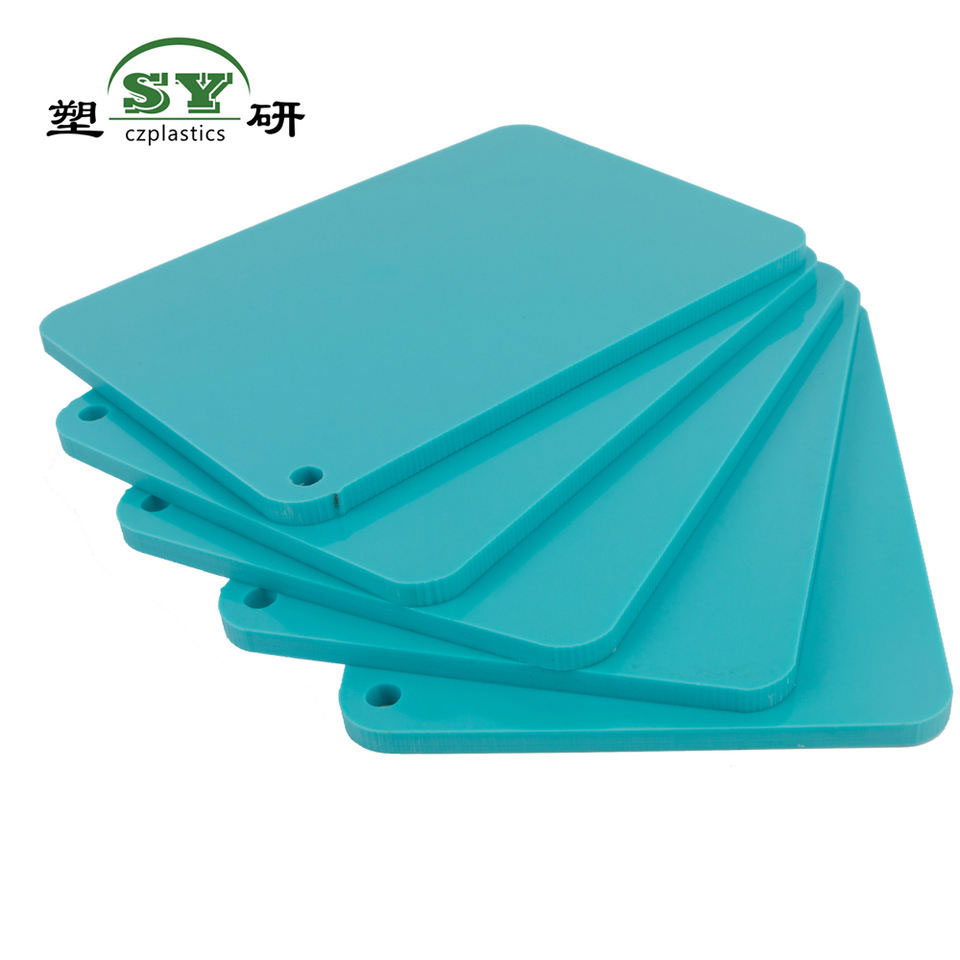

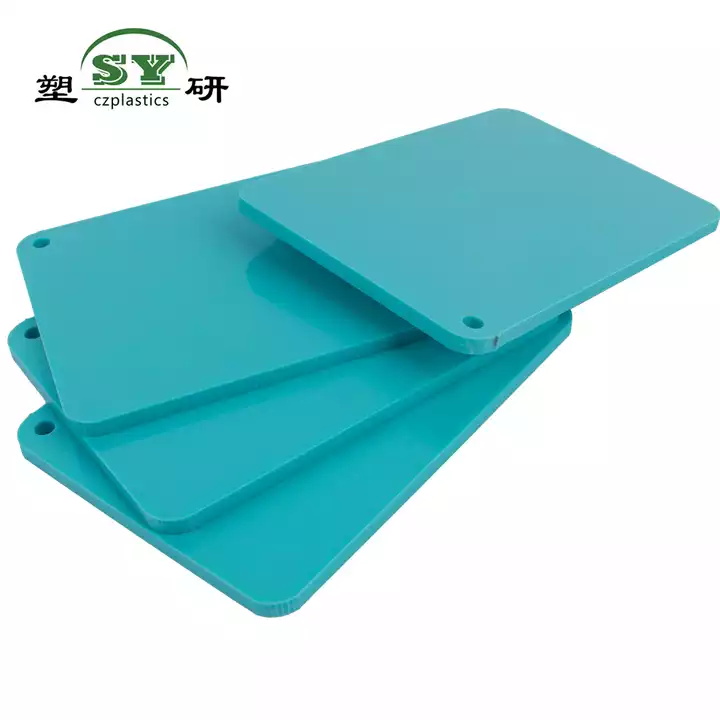

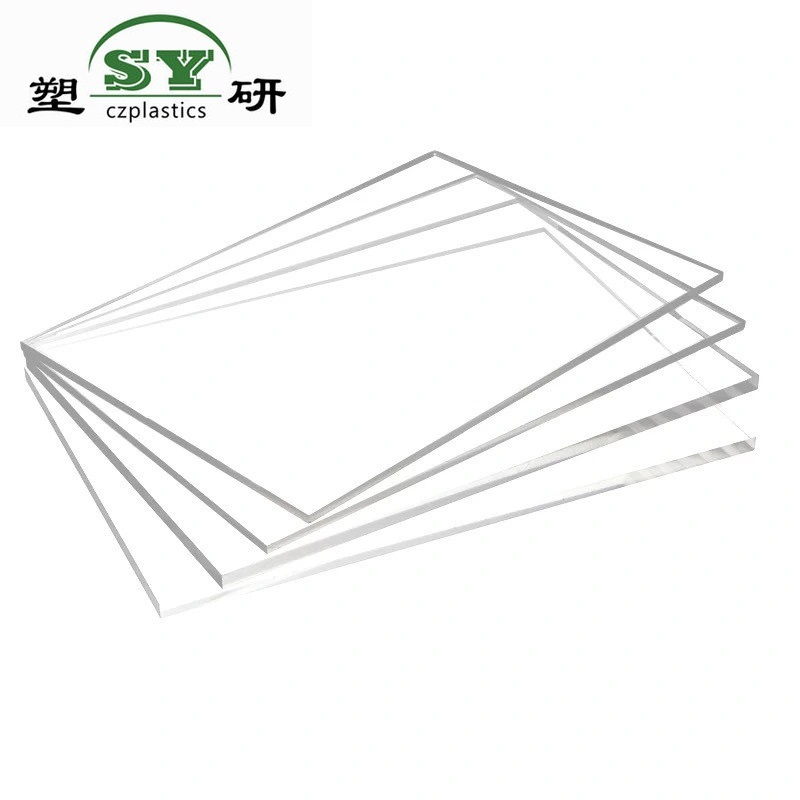

HIPS Fridge Board

Our HIIP Fridge Board has high gloss, comparable with ABS, and low cost. Changzhou Plastics Researching & Manufacturing Co., Ltd has obvious advantages in the industry. It has a production scale, variety, production technology, technical equipment, quality control, customer resources, new product development, etc.